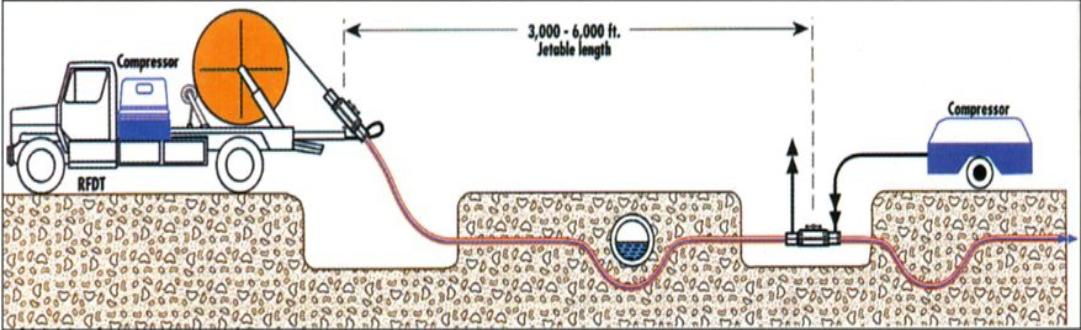

Jetting is an internationally patented method for installing fiber optic cables in duct utilizing a balance between a low-strain pushing force and high

speed air flow. A drag force is distributed along the entire cable length moving the cable through the duct without an exponential build-up of pulling

forces in curves and undulations, such as occur when traditional pulling methods are used.

Jetting uses no "closed-end" shuttles or air capturing

devices at the cable-end which creates significant pulling forces.

|

|